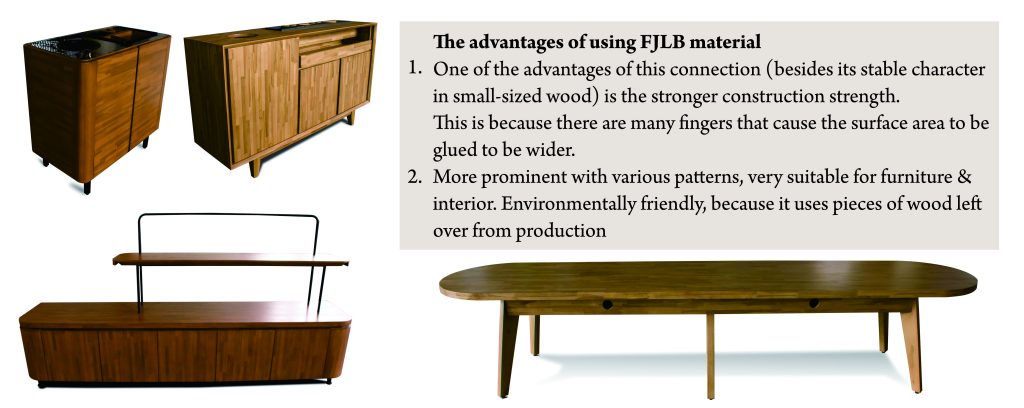

There are many materials that we can use to make furniture, and of course, each of them has its own advantages and disadvantages. In this article, we will talk specifically about FJLB (Finger-Joint Laminate Board) material. FJLB is a small piece of solid wood that is joined together, like barecore, but joined with finger-joint joints so that it is tidier and stronger. This process involves cutting the ends of the pieces of wood at a 45-degree angle and then gluing them together, creating a strong, stable board. In this article, we will explore the properties of finger joint laminated board and why it is considered a suitable alternative to solid wood

This type of construction is highly favored by furniture manufacturers, especially mid-to-high-end manufacturers. The reason is because the nature of this connection is stable in small-sized wood. In terms of strength, it is very strong in the furniture industry and certainly stable and does not warp compared to solid wood.

FJLB is commonly used for

– Cupboard

– Toptable

– Door

– Kitchenset

– Cabinet

The disadvantages of FJLB are

1. Not suitable for furniture that requires strength to withstand excessive weight for a long time, for example chairs

2. The working process for this type of construction is longer than other constructions.

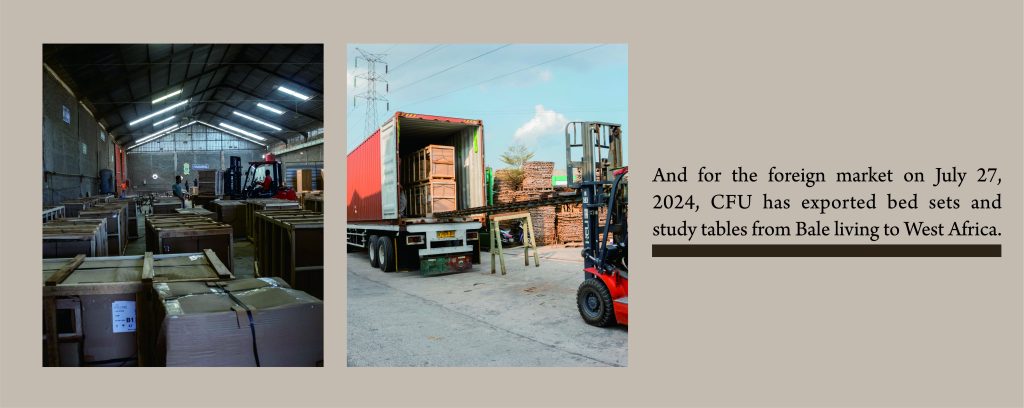

FJLB itself is mostly exported abroad and FJLB there is a primadonna. Citra Fajar Utama (CFU) has been producing FJLB for many years. These FJL boards are reprocessed to make tables, top tables, door and cabinets. In the local market CFU has become a supplier of furniture made from FJLB for one of the international cafe brands located throughout Indonesia.